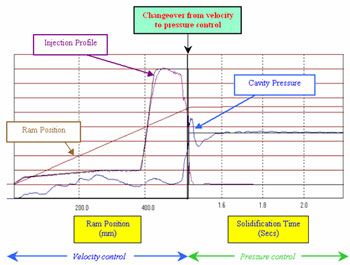

Most of the prototype copper rotors produced for the ICA/CDA project were cast using a Buhler 660 metric ton machine, similar to that shown in Figure 11.6.1. Similar to most modern die-casting machines, this Buhler machine can record and document shot profile data for each rotor. An example of a shot curve used to die-cast a copper rotor is shown in Figure 11.6.2. The process parameters used to cast the rotor are listed in Table 11.6.1.

Figure 11.6.1: Buhler die-casting machine

Figure 11.6.1: Buhler die-casting machine| Parameter | Value |

|---|---|

| Slow shot plunger velocity | 0.26-0.50 m/sec |

| Fast shot plunger velocity | 4.0 m/sec |

| Intensification pressure | 920 bar |

| Solidification time | 12 seconds |

Figure 11.6.2: Example of a shot curve from a die-cast copper rotor (process parameters used to produce the rotor are listed in Table 11.6.1)

Figure 11.6.2: Example of a shot curve from a die-cast copper rotor (process parameters used to produce the rotor are listed in Table 11.6.1)Although the level of process monitoring described here is not necessary for the production of die-cast copper rotors, it obviously provides valuable information to the die-casting engineer during initial set-up of the process, and to ensure that the process remains in control during commercial production. If older die-casting machines are being used that don't have such process monitoring, retrofit systems can be used from companies such as Visi-Trak. The Visi-Trak True-Trak 2020TM monitoring system features a high-speed data collection system that records injection data from position and velocity sensors. In addition, the Visi-Trak Sure-Trak2TM shot control system can be used to replace the valves and control systems on older machines, to provide real time control of the injection process.

Contact information for Visi-Trak is listed in Table 11.6.2.

| Company Name | Contact Person | Location | Phone Number | E-mail Address | Web Site |

|---|---|---|---|---|---|

| Visi-Trak | Jack Branden | Valley View, Ohio, USA | +1-216-524-2363 | sales@visi- trakworld wide.com |

www.visi-trak worldwide.com |