Greening Fire Sprinkler Systems with Copper

In today’s construction environment, architects, engineers and builders have a new mantra: Make it efficient. Make it sustainable. Make it green.

This imperative extends throughout the building envelope to materials and building practices, and also to mechanical systems such as heating, air conditioning and water supply systems, including fire sprinkler systems—a critical component of commercial and, increasingly, residential structures.

While various piping materials can be used for sprinkler systems, copper is often recommended, especially in systems or applications where the delivery of clean water from the system is desired to minimize permanent staining and damage to the building contents.

Copper can also claim to be the “greenest” of all metals used in buildings in general and sprinkler system design in particular. Copper’s recyclability and long lifespan are key attributes that can help a structure achieve green building certification.

There are many other reasons why copper tube and fittings are ideal for fire sprinkler systems:

- Fire Resistance – Unlike some piping materials, copper does not burn, support combustion or emit toxic fumes when exposed to flame. It will not transport fire through floors, walls and ceilings, and it maintains constant water pressure when heated. Although fire temperatures can easily reach 1,500°F, copper has a melting point of nearly 2,000°F, making it impervious to even extreme heat.

- Superior Flow – Preventing capacity loss is critical to maximizing a system’s effectiveness. Thin-wall copper tubing offers superior flow rates compared to other, similar-size pipe materials. The oxide film that forms on the inner surface of copper tubing acts as a protective barrier against fire and does not flake off, reducing the potential that a system will clog.

- Ease of Installation – From initial delivery to installation of the last sprinkler head, lightweight copper tubing helps get jobs done quickly. Copper is also easy to transport, store and handle, unlike competing materials such as heavy steel pipe and fragile plastic system components. With small-diameter copper tubing, installations typically require less labor and result in less damage to building interiors. And when repairs or retrofits are needed, these attributes help expedite work while minimizing occupant downtime.

- Sustainability and Cost – While initial installation costs may be higher, the longevity, durability and dependability of copper systems make them competitive and even lower in cost over the long run. Copper is also 100 percent recyclable, so additional cost can be recovered when a building is demolished or the system is removed.

In today’s green building environment, copper offers many advantages, not least of which is that virtually all copper tubing contains pre- and post-consumer content, a requirement of green building guidelines. While copper may be considered a “red” metal by those in the industry, it is truly the greenest of material.

Also in this Issue:

- Going by the Book

- Greening Fire Sprinkler Systems with Copper

- What Would Al Gore Choose?

- Copper's Design Potential Highlights Architectural Seminars

- Return to Glory

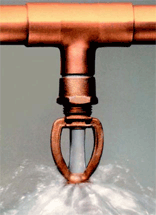

Activated copper sprinkler system delivers clean water.

Activated copper sprinkler system delivers clean water.