The outstanding characteristics of copper, which apply also to copper P/M parts, are high electrical and thermal conductivities, ductility and corrosion resistance. Many applications of copper and copper alloy P/M parts are based on these characteristics.

Copper powder with a purity of more than 99% copper is available commercially, and parts produced from these powders have electrical conductivities of 80% to 95% IACS as pressed and sintered. Higher conductivities, approaching 100% IACS can be achieved by further densification. High electrical conductivity also means high thermal conductivity. Thus, copper P/M parts have a significant advantage for the production of electronic and electrical components, where electrical or thermal conductivity is an essential attribute.

Copper is a very ductile and malleable metal. Parts produced from copper and copper alloy powders also have excellent ductility. The elongation of pressed and sintered P/M copper, brass and nickel silver parts ranges up to 35% in one inch.

Copper and copper-base alloys are resistant to a wide variety of corrosive environments. P/M parts produced from copper, bronze, brass, nickel silver and copper-nickel have corrosion resistance properties essentially equivalent to those of their wrought or cast counterparts.

The applications of these P/M materials are based on a combination of properties, rather than on a single one. The following case histories indicate that selection is based not only on conductivity, ductility and corrosion resistance but also on strength, ability to hold close tolerances and cost reduction.

Copper P/M Parts

Components for switch gears were converted to copper P/M parts from wrought copper to achieve a considerable reduction in cost while still maintaining good electrical conductivity. The components are used in switch boxes with capacities up to 600 amperes.

Because of its excellent thermal conductivity, a P/M copper component weighing 1/2 pound was selected for a heat sink in an electronic application.

Components for 150- and 250-ampere fuse blow-outs, used in coal mining equipment were converted from machined copper bar stock to a P/M copper part. Although drilling and tapping were still required, the conversion resulted in cost savings of about 25%.

Back to TopBronze P/M Parts

A P/M bronze cam was developed to advance the film, frame by frame, at the rate of 24 frames per second for 8- and 16-mm projectors. The shape was a circular arc with a 126-degree dwell surface. Wear resistance was a requirement because the cam operated against hardened and polished cam shoes. A leaded bronze was selected that met the close tolerances demanded of this part without machining.

A P/M bronze gear and ratchet for dial telephones was selected as a replacement for a cast and machined brass assembly and by eliminating machining, reduced costs by 25%.

P/M bronze pantograph shoes are used on Japanese railroads because they offer low contact resistance, high strength, and low maintenance cost. For normal use, the alloy is 80Cu-10Sn-5Fe-5graphite. In areas where corrosion is a factor, the iron content is increased and nickel is added with a corresponding reduction in the copper content.

Back to TopBrass P/M Parts

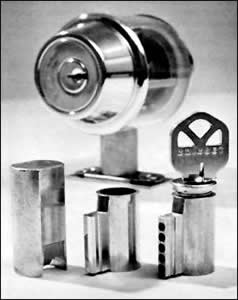

Leaded brass (78Cu-20.5Zn-1.5Pb) was selected for a latch bolt and cylinder for an extra security double cylinder lock. Redesigned from die-cast and machined parts, the P/M components provided improved strength and tolerances and a better design at an economical cost. The latch bolt is compacted, sintered, coined and annealed to a density of 7.8 g/cm 3 with critical tolerances held to 6-8 mils. The bolt houses a 3/8-in. hardened steel pin to prevent sawing. The bolt can withstand a 450-pound blow without breaking. The cylinder body is compacted, sintered and coined for dimensional control and has a minimum density of 7.6 g/cm 3. The lock, which is surrounded by two free-turning P/M steel rings and has tempered P/M steel cylinder guards, has passed rigid break-in tests and meets HUD requirements.

Figure 9. Brass Cylinder and Latch Bold used in High Security Lock.

Figure 9. Brass Cylinder and Latch Bold used in High Security Lock. Figure 10. Brass diverter valve bodies and assembled valve for water-purifier unit.

Figure 10. Brass diverter valve bodies and assembled valve for water-purifier unit.A P/M brass diverter valve body is used in a home water softening and purification faucet unit. The unit removes chlorine, sulfur, rust, scale, algae and most additive chemicals. The complicated part has eight levels and is fabricated from brass powder to a minimum density of 7.6 g/cm 3. It is impregnated with a plastic to assure pressure tightness and is finished by chrome plating.

A leaded brass (78Cu-20.5Zn-1.5Pb) was selected for the rotor of a clockwork delay mechanism of a fuse for a 40-mm projectile used in shoulder-fired weapons. The part prevents detonation of the round before it has reached a safe distance from the muzzle of the weapon. The rotor is fabricated to a minimum density of 7.7 g/cm 3. It is produced at high production rates to tolerances of 2 mils on both the solid hub and the hollow hub.

A similar leaded brass was selected for the gear rotor in the timing mechanism of a mechanical fuse which serves as a safety and arming device for 40-mm projectiles used in helicopter cannon. The part is fabricated to a density of 7.7 g/cm 3 and tolerances are held to 0.8 mils on gear teeth that are only 0.013 in. thick.

Figure 11. Brass rotor for ordnance fuse.

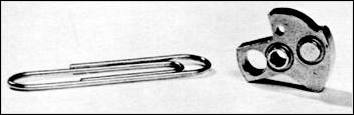

Figure 11. Brass rotor for ordnance fuse.A gland to prevent the turning of a valve stem with subsequent grinding of the seat washer against the seat was originally made of extruded brass stock. A noncircular hole was shaped during extrusion but required broaching and all shaping was done on a screw machine. Converted to a brass P/M part, no machining was required with a resulting cost reduction of 40%.

P/M brass (85Cu-15Zn) has been pressed, sintered and coined to produce blanks that have excellent coinability and produce sharp impressions in the production of medallions.

Back to TopNickel Silver P/M Parts

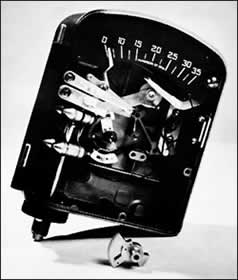

Nickel silver (64Cu-18Ni-18Zn) was selected for a new design of a gear and cam that replaced more than 21 parts in an automotive recording tachometer. The P/M part drives the pointer and recording unit and offers a cam surface which acts as a contact and ground to turn on an internal warning light and an audible warning signal. The part is fabricated to a density of 7.2-7.6 g/cm 3 and close tolerances are held on the 22 gear teeth and the center of the hub. The tachometer is used on heavy long-distance trucks, off-road equipment, emergency vehicles and fleet cars.

Figure 12. Nickel silver gear and cam for automotive recording tachometer.

Figure 12. Nickel silver gear and cam for automotive recording tachometer. Figure 13. Brass gear rotor for timing mechanism in mechanical fuse.

Figure 13. Brass gear rotor for timing mechanism in mechanical fuse.Nickel silver P/M parts were selected for activator bars for repeat-cycle timing and control devices to meet corrosion and wear resistance requirements. The parts have a sintered density of 7.7 g/cm 3, a tensile strength of 35 ksi (241 MPa) and an elongation of 35% in one inch. They are used in electromechanisms for aircraft, scientific equipment and pre-set motor operations.

A brush holder for a miniature D.C. motor, rated 0.045 hp at 16,000 rpm, is 1.875 inches long and 1.250 inches in diameter. Produced from nickel silver powder, the part meets the requirements for corrosion resistance and a component-life test of 3,000 hours without fatigue failure.

A thrust bearing assembly for a submersible gasoline pump consists of a face plate and an angle plate produced from nickel silver powder. These parts were originally machined from stainless steel. Production by P/M procedures eliminated machining and produced equivalent hardness and wear resistance at a saving of over $2 per set.

An insert to provide contact points for the stator winding of a synchromotor assembly was converted from an assembly of 13 parts to a single nickel silver P/M part. In the new design, the P/M insert is embedded in a molded plastic block. The ends of the block and the base of the nickel silver part are machined to leave exposed metal segments, which are drilled and tapped for wiring connections.

Back to Top