Property Data on The Copper Page

Copper Applications in Innovative Technology

- How can one obtain more information on gear bronzes? Applications, mechanical properties, benefits/drawbacks, studies, etc.?

- I am trying to find a copper or copper alloy good for annealing. We are trying to fabricate a soft gasket for a large pump.

- I would like information on Compressed Air and Steam flow capacities for Copper Tubing.

- Standard Mechanical and Physical properties for each alloy would be extremely useful.

- I was looking for specific information concerning various hydraulic fluids and their compatibility with copper tubing.

- More on engineering parameters, i.e. elongation, safety factors in design (ksi designed to), fatigue lifetime cycles.

- Where are the machinability ratings?

- I need to know about the percentage of copper in brass.

- No mention of the appropriate copper alloys for bearings and what the tradeoffs are in selecting between them such as hardness, wear resistance, material compatibility, price, availability, etc. The engineer needs information to make informed choices.

- I would like to see more applications of bronze in connection with spherical plain bearings.

At The Copper Page we regularly receive user evaluations and email like those above requesting data on copper's properties and uses. In order to help fill these needs a new web site will soon be released which will make available an expanded version of the data which has been traditionally found in Copper Development Association Inc's Standards Handbook series. This site, along with the property data already available on The Copper Page, will provide users extensive data on the properties of over 300 copper alloys (not all the information will be available at first).

Types of Data Available

Property data is information that describes how a material behaves under different circumstances. Property data is essential to design new products, determine if a product can fill a particular need, or analyze problems with an application.

In The Copper Page our properties section includes information on composition, structure and uses which, while not strictly properties, help users better understand the alloys. With the release of our properties database The Copper Page will contain extensive information on the following:

- Mechanical Properties

- Physical Properties

- Fabrication Properties

- Corrosion

- Typical Uses

- Microstructures

- Composition

Mechanical Properties: The most important set of properties for designers and users of materials are usually the material's mechanical properties. Mechanical properties describe how a material behaves when force or stress is applied to it. These properties are typically highly dependent on how the material was processed after it was created. Material properties include various types of strength, hardness, and ability to resist stretching. This is important as it provides information on whether or not a material will break or bend when used. Specifically, the properties database contains information on: hardness (Brinell, Charpy, Izod, & Rockwell), strength (Compressive, Shear, Tensile, & Yield), and Elongation.

Physical Properties: An alloy's physical properties are considered to its traits that are inherent within it and do not depend on how it is processed. In the properties database there is information on the following physical properties: melting points, electrical & thermal conductivity, density, rigidity, Specific Gravity, Specific Heat Capacity, Elasticity amongst others.

Fabrication Properties: Fabrication properties are characteristics of an alloy that are important when manufacturing a product from the alloy. The properties database includes information on: Joining (soldering, brazing, five types of welding), capacity for being cold worked or hot formed, and forgeability and machinability ratings.

Corrosion: Corrosion is a chemical reaction between a material and its environment which causes a deterioration of the material. Ensuring that materials are not used in environments in which they are likely to malfunction or fail is extremely important. It is especially difficult to provide useful corrosion data because the rate and method by which a material corrodes depends on a large number of variables making it almost impossible to provide detailed numeric data that covers a user's specific needs. Because of this The Copper Page has decided the most useful contribution it can make to help users understand copper's corrosion behavior in various environments is a summary of how various alloys behave in different environments. A large searchable database is available which allows users to find the corrosion resistance of copper alloys in almost 200 different environments, ranging from Beer & Fruit Juices to Sulfuric & Hydrochloric Acid. This database was created by conducting an extensive review of the literature on copper and corrosion and summarizing the results.

Uses Data: Uses data is a summary of the applications an alloy is typically used for and why it is used. When designing a product the designer typically knows what the product is and what special requirements it will face. For instance, the first question to CDA's PC based CopperSelect Materials Selection Guide from outside users was "Which alloy should I use to cast gears that will be heavily machined?" One approach to answering this question is to determine what properties are needed for gears in general. Tensile strengths, yield strengths, corrosion resistance levels, price, etc. must all be specified to be sure the materials on the list are really suitable for the task. If the designer does not know what levels of corrosion resistance or what tensile strengths are required in gears he will not any way to obtain an acceptable list of candidate materials. Even if he does know the proper criteria it is almost certain that he will not have all the data needed.

To deal with this problem some years ago CDA embarked on a "Typical Uses" project. CDA's literature was reviewed and copper fabricators and others were queried on the applications coppers and copper alloys are used for and why they are used. The result was an applications database of the strengths of each copper and copper alloy and the applications it is typically used for. By using the Typical Uses Database the designer can ask: which alloys are gears made from and then look at the machinability ratings of those alloys.

Typical Uses of Copper and Copper Alloys Search Results

| Alloy | Category | Use | Reason |

|---|---|---|---|

| C10100 | Electrical | Anodes for Vacuum Tubes | Electrical Conductivity |

| Anodes for Vacuum Tubes | Thermal Conductivity | ||

| Anodes for Vacuum Tubes | Corrosion Resistance | ||

| Bus Bars | Electrical Conductivity | ||

| Bus Bars | Weldability | ||

| Bus Conductors | Electrical Conductivity | ||

| Bus Conductors | Thermal Conductivity | ||

| Bus Conductors | Corrosion Resistance | ||

| Bus Conductors | Solderability | ||

| Coaxial Cable | Electrical Conductivity | ||

| Coaxial Tube | Electrical Conductivity | ||

| Conductors | Electrical Conductivity | ||

| Conductors | Thermal Conductivity | ||

| Conductors | Weldability | ||

| Glass-to-Metal Seals | Will not Hydrogen Embrittle during Brazing | ||

| Glass-to-Metal Seals | Low Oxygen Content | ||

| Glass-to-Metal Seals | Electrical Conductivity |

Uses Database Result

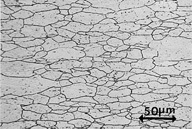

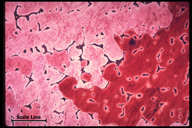

Microstructures: The microstructure of a material is its structure at a very detailed level. By examining the microstructure (typically with a 50 to 1000 times magnification) engineers and others are able to understand and predict an alloys behavior and properties. More information on examples of microstructures of a number of alloys processed in various ways is available on Microstructures of Copper and Copper Alloys page.

|

|

|

| Copper Microstructures | ||

Composition: The first level of identification for copper alloys is their composition. A listing of the composition of commercially active alloys is available on our Standards & Properties section.

Status

A beta version of the Properties Database has been completed and is currently being reviewed in insure the accuracy of the data. Once this is done the site will go on-line.

Also in this Issue:

- Power Quality and Your Computer

- Property Data on The Copper Page

- Summary of 1999 Detroit International Auto Show and Potential Changes in Copper Content