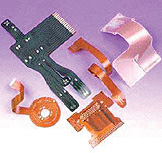

Flex Copper Circuits: Clean and Conductive

Electronic equipment can now be made less expensively as a result of a new copper technology. Recently, an innovative way of printing flexible circuits, used in computers, calculators, cell phones and other electronic equipment, has been developed to deliver very thin lines of copper exactly where it's needed on flexible circuits. It involves electroless inkjet plating.

Currently, a sheet of copper is laminated to a flexible film, and then much of the copper is etched away, resulting in thin lines of solid copper that carry current. The new method uses inkjet technology to deposit only thin copper lines onto the circuit, eliminating waste and making circuits less expensive to produce. The electroless plating method results in much better electrical conductivity in the circuit than is possible with silk-screen technology. Very small thicknesses of copper, between 0.05 microns and 5 microns, are made possible by this new method. This makes it ideal for RFID (radio frequency identification) tags and heater circuitry, according to Tom Woznicki, president of Flex Circuit Design Co.

The new method was developed by a partnership between Conductive Inkjet Technology of Cambridge, England, and Preco, Inc. of Lenaxa, Kansas, and has not yet been widely used. Cu

Resources:

Also in this Issue:

- Wind Power: A Positive Future

- Motor Rotors

- Flex Copper Circuits: Clean and Conductive

- From Copper to Bronze to Conquest

- CPUs Reach Their Potential Through Copper: The Hottest Computers Depend on Copper