Copper’s Millennia-old Role in Conflict

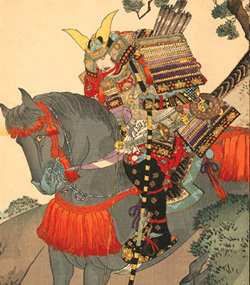

A 19th-Century Japanese wood-block illustration showing a mounted eleventh-century samurai named Minimoto. Often armor such as Minimoto's was held together with copper, brass or bronze wires and the iron helmets, as depicted in this illustration, were commonly decorated with copper or brass. The hilt of Minimoto's sword was also made of brass, as was often the case with such ancient weapons.

A 19th-Century Japanese wood-block illustration showing a mounted eleventh-century samurai named Minimoto. Often armor such as Minimoto's was held together with copper, brass or bronze wires and the iron helmets, as depicted in this illustration, were commonly decorated with copper or brass. The hilt of Minimoto's sword was also made of brass, as was often the case with such ancient weapons.Copper and its alloys, especially bronze, have been essential in warfare for nearly 5,000 years in both offensive and defensive operations. Even today, many of the copper alloys, especially brass, are still widely used in weaponry.

- For millennia, copper, and then bronze, were the dominant materials for the best hand weapons of the day, including arrowheads and spear tips.

- Bronze was also the material of choice for armor to protect both men and horses for thousands of years.

- Chinese war chariots used bronze fittings.

- Bronze dominated the manufacture of cannons for centuries.

- Today, brass is the standard material for ammunition cartridge casings used for both bullets and artillery ordinance.

- However, it's the dependable high electrical conductivity of copper which is most prized by today's military, for its use in powerful motors to drive large vehicles, electronic equipment and controls, and to provide secure means of communication around the world.

Some 5,000 years ago, edged stones in maces were replaced by sharper-edged copper, and then by harder bronze as it became available. Even after steel replaced bronze in sword blades, the hilts were often still made of non-corroding brass, according to military historian H. David Whieldon. Scabbards for these swords were often made of non-rusting and very decorative bronze. Several examples are on display at the British Museum in London.

When warriors began constructing metal body armor, bronze was the metal of choice for the intricately designed helmets. Later, overlapping bronze scales were laced or sewn onto padded fabrics. Long after the introduction of iron and steel armor, bronze was still widely shaped into armor because it could be worked into much larger pieces than other metals. In addition, ferrous armor was sometimes covered with non-rusting copper alloys (see photo) to enhance its appearance and allow for significantly less maintenance. Bronze alloys were also used to fashion hardware for Chinese war chariots, examples of which can be found on display at the Metropolitan Museum of Art in New York City.

Copper's Strength Shines

Although the first crude cannon was made of iron, by the 16th Century, cast bronze dominated "because it was stronger than the cast iron of the day," according to Robert Fisch, curator of arms at the West Point (New York) Museum. Even as the quality of iron and its methods of fabrication improved during the Civil War, some small bronze artillery was still in use late in the 19th Century. Early on, some handguns had bronze barrels, but iron soon dominated there as well.

Bronze's ancient role in naval warfare was highlighted by the hull-piercing, bronze-shod rams on the outnumbered Greek warships that defeated the Persian fleet at the battle of Salamis (480 B.C.). Interestingly, iron replaced bronze earlier in cannons on warships than in land artillery. Because naval warfare prior to the late 19th Century was at close range, the greater strength of cast bronze was not as necessary, notes Fisch.

Wooden warships were also protected with biostatic copper sheathing below the waterline to prevent the growth of speed-reducing incrustations of barnacles. This copper sheathing also offered an unanticipated benefit to wooden ships. When the lone operator of a hand-powered submarine, built by Yale student David Bushnell during the Revolutionary War, attempted to attach a mine to a British warship in New York harbor, he failed because his drill couldn't penetrate the copper sheathing on the ship's hull.

Today, of course, copper plays many critical roles in modern naval warfare, but mostly as an electrical conductor. For example, U.S. Navy ships and submarines have propulsion systems driven by copper-wound motors. Often the propellers themselves are made from cast copper alloys. And military land operations depend on communications carried over copper wires. During the current billion-dollar renovation of The Pentagon, no less than 16,000 miles of new copper telephone and data cable is being installed.

From Copper to Brass

The first ammunition with metal cartridge casings—produced with an alloy that was over 90% copper-was introduced by the French in the 1840s. An alloy of copper was chosen because it was easy to work with, and because the ferrous metals tended to rust. The high-copper-content alloys were gradually replaced by harder alloys containing less and less copper. This was necessary because the softer cases would sometimes expand too much after the bullet was fired and stick in the breach, notes Fisch.

By the 1880s the cases were distinctly brass, which is still widely used in bullet and shell casings. For example, at Remington Arms, Raleigh, North Carolina, a 70% copper, 30% zinc alloy is used for the bases of shotgun shells, according to a Remington spokesman. Rifle cartridge shells are generally made from alloy C26000, which is 70% copper. The U.S. Army began using brass cases for shells for breach-loading artillery in 1885, according to Fisch.

There's still another interesting application for copper in ammunition. As bullets were fired from small arms at ever-higher velocities, the soft lead began to strip, thus failing to engage the rifling. To correct this problem, the Swiss began coating their lead rifle bullets with copper back in the 1880s. Today, copper is still widely used for jacketed bullets in which the lead is encased in a thin coating of copper.

Japan Gallery: 212/288-2241

Metropolitan Museum of Art: 212/535-7710

West Point Museum: 845/938-3627

Also in this Issue:

- Munch Chocolate for Health

- Copper’s Millennia-old Role in Conflict

- Outdoor Copper Enhances Homes

- Proof of Copper's Indispensability

- Copper Crowns Transportation Hub