What is Wind Energy?

Wind energy is a form of solar energy. Wind is caused when the sun heats air and land unevenly. Geological irregularities and the earth's rotation are also at play. As air is heated, it rises and cooler air quickly falls to fill in the space. This causes air mass movement. For centuries people have harnessed the energy produced by the wind. Today, large and small-scale wind turbines transform the kinetic energy of wind into electrical energy for individual and commercial use. Wind energy is the fastest growing energy source worldwide.

Photo courtesy of Free Photo Bank.

Photo courtesy of Free Photo Bank.Wind Turbine Basic Facts

Wind turbines are named based upon the orientation of the rotor blade axis. Vertical turbines have a vertical axis and are also called "egg beater" turbines. This style is less common than the conventional horizontal axis. Horizontal turbines, which have a horizontal rotor blade axis, are the most popular design and have the most wide spread usage.

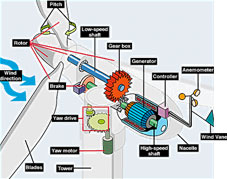

Parts of a Wind Turbine

See U.S. Department of Energy for more information.

See U.S. Department of Energy for more information.Wind turbines are placed on towers reaching anywhere from 40 - 90 meters high. Because there is less air turbulence at greater heights, wind turbines are most effective mounted on tall towers. The towers are constructed of steel. Electrical equipment, primarily wire, runs through the steel towers so that the energy can be dispersed to either an individual client or transported to the electrical grid.

Grounding equipment is found at the base of wind turbine towers. It is crucial that wind turbines have a way of dissipating the energy and protecting the mechanical components from lightning strikes and with increased tower height; the risk of lightning strikes also increases. Grounding equipment, primarily copper, helps to protect the turbines, and people, from lightning strikes.

Size

See U.S. Department of Energy for more information.

See U.S. Department of Energy for more information.Recent developments in offshore wind turbine construction have allowed for great size, and therefore greater energy production. An average offshore wind turbine has a blade diameter of 110 meters. The greater size is due in large part to the fact that it is easier to transport the large-scale equipment by ship than by land.

Wind Energy Outputs

The energy output of wind turbines is measured in watts, kilowatts, and megawatts. The energy output designation is based upon how much energy the wind turbine produces in one year. For example, a 10 kilowatt turbine produces 10 kilowatts of energy per year, which is enough energy to power the average family home for one year. One megawatt of electrical energy is enough to power 225 - 300 typical American homes.

Wind Farms

To produce energy on a large scale, wind turbines are grouped together to create wind farms. Wind farm energy production ranges from a few megawatts to hundreds of megawatts. Because large-scale energy production is desired through wind farms, large, commercial grade wind turbines are used. These large-scale wind turbines have energy production rates of 750 kilowatts to 2.5 megawatts. If you were to group such wind turbines together into a wind farm you would get the follow energy outputs: ten 700 Kilowatt machines would produce 7 megawatts of energy while ten 2.5 megawatt machines would produce 25 megawatts. The resulting production of 25 megawatts of energy is enough to power 5,600 - 7,500 American homes.

While wind farms take up a large amount of land, since each turbine requires approximately 2 acres of land, the relative impact can be minimal. This is due to the fact that wind farms can be built in agricultural areas without disturbing the farmland. The land can continue to be farmed or grazed, with the farmer earning additional income by renting the land to the wind farm proprietor.

Advantages of Wind Energy

The greatest advantage of wind energy is the fact that it has zero carbon emissions. The energy source is free, illimitable, and cannot be subject to trade embargoes. Wind turbines are very reliable, with a 98% availability rate. Availability rate refers to the percentage of time a power source is functioning as opposed to being shut down for repairs or maintenance. Wind turbines are extremely reliable, needing minimal maintenance and repair.

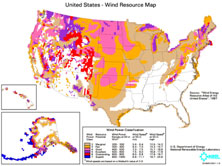

Wind power is readily available in the United States, with 46 out of 50 states having areas that are windy enough to be developed for wind power. The highest concentration of prime wind production land lies in the central region of the country, from Minnesota to Texas to Wyoming.

High-resolution version of this photo.

High-resolution version of this photo.Because wind is intermittent, at this time wind power is not being touted as a total energy solution. Instead, wind power will be one of a variety of energy sources available through an energy pool. It is widely held that wind power could easily be used to cover 5% of the U.S. energy production, with a possible 10% wind power production world wide by 2017.

Development of 10% of the energy potential in the 10 windiest states is enough to reduce U.S. carbon emissions by almost 1/3, and world emissions of carbon dioxide by 4%. It would greatly reduce acid rain and our dependence on fossil fuels. If wind power could produce 20% of the U.S.'s energy it would displace more than 1/3 of the emissions from coal burning power plants, or all of the nuclear waste and water pollution from nuclear power plants. These changes would have a great positive environmental impact on our country and worldwide.

The demand for wind turbines will create jobs in both the fabrication and installation of wind farms. Wind energy production will bring much-needed jobs to rural areas. Additionally, wind farms can bring additional income to farmers through land leases. Increased development of wind energy will have a positive economic effect beyond energy cost savings making wind energy both economically and environmentally advantageous.

How Copper Helps Make Wind Energy Possible

The primary use of copper in wind energy technologies is in the coil windings in the stator and rotor portions of the generator, in the high-voltage power cable conductors, and in the transformer coils. Copper is vital to the electrical grounding system for wind turbine farms. The turbine masts are prime attractors of lightning strikes, so they require a lightning protection system. When lightning strikes a turbine blade, the current passes along the blade, through the blade hub in the nacelle (gearbox/ generator enclosure) and down the mast to a grounding system. The blade incorporates a large cross-section copper conductor that runs along its length and allows the current to pass along the blade without deleterious heating effects. The nacelle is protected by a lightning conductor, often copper. The grounding system, at the base of the mast, consists of a thick copper ring conductor bonded to the base or located within a meter of the base. The ring is attached to two diametrically opposed points on the mast base. Copper leads extend outward from the ring and connect to copper or copper-clad grounding electrodes. The grounding rings at all turbines on the wind farm are inter-connected, providing a networked system with an extremely small aggregate resistance.

According to the American Wind Energy Association (AWEA), most wind farms have numerous features in common, including a single turbine with a connection to a generator and a step-up transformer, and medium-voltage collector systems and interconnect equipment.

How Much Copper Is Used In A Wind Farm?

In 2006, CDA asked Oak Ridge National Laboratories (ORNL) to evaluate the use of copper in renewable energy sources. ORNL conducted an analysis on the Buffalo Mountain Wind Farm run by the Tennessee Valley Authority (TVA) and developed the following information.

The Buffalo Mountain Wind Farm has two types of turbines, Vestas Model V47 and Vestas Model V80. For the Vesta V47, a 660-kW turbine, the windings in the system total approximately 800 lb of copper. There are three of these turbines. Three 2/0 cables each 270 ft long connect the generator at the top of the tower to the controller below. Approximately 100 lb of copper busing are located at the base. In addition, the control cabinet contains about 300 lb of various small gauge wires. Each tower has a grounding system that consists of a 1/0 copper cable that runs the length of the tower. Several circular rings of this cable surround the tower. The base of the tower is about 39 ft. Three 20 ft long copper grounding rods, about 1/2" in diameter are associated with each tower.

There are 15 V80 turbines rated at 1.8 MW each. The cable connection is 4/0. The transfer cabinet contains about 15 lb of copper. From the transfer cabinet, either 2/0 or 3/0 cable conveys the energy underground to a switch yard or collection point. From there, aluminum overhead transmission cable distributes the energy away from the farm.

Obviously, the outstanding conductivity and durability of copper help make wind energy generation efficient and reliable. As the U.S. begins to focus more attention on renewable energy sources, copper will play an important role.

Additional Sources of Information

Wind Energy Development Program Information Center

U.S. Department of Energy - Energy Efficiency and Renewable Energy