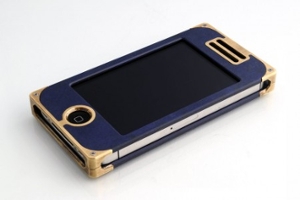

Brass Pocket Sculpture

Front cover of EXO15 Brass Blue Composite by Exovault.

Front cover of EXO15 Brass Blue Composite by Exovault.Artists Amelia Biewald and Jonathan Schipper were taking a ride on the subway in New York, after the first iPhone came out, when they had a realization.

“‘Everybody has the same, ugly plastic case, probably made in China by the millions,” Biewald thought at the time. “There has to be a better thing out there. We can make something like this.’”

This awareness led to a desire to merge quality craftsmanship and their backgrounds in sculpture to form Exovault, a business centered on making unique covers for the iPhone 4, iPhone 3G, iPhone 3GS and iPod Touch. They have designs in the works for iPad covers as well. All of their cases are designed, manufactured and assembled by hand in their studio located in Brooklyn, New York.

Their backgrounds as sculptors give them an artistic edge in bringing their visions to life. Schipper and Biewald’s dedication and attention to detail is evident in each of their designs, made of various materials, including brass, aluminum, steel, wood and plastics. Exovault currently offers nine different brass cover designs on their website, which range in price from $95 to $230 for an engraved cover. The brass covers will naturally patina specific to use.

Back cover of EXO15 Brass Pao Ferro Composite with Western Engraving by Exovault.

Back cover of EXO15 Brass Pao Ferro Composite with Western Engraving by Exovault.The copper alloy they use is a C280 alpha-beta brass made with approximately 60% copper and 40% zinc. The alloy 280 Muntz Metal, which they purchase at Rotax Metals in Brooklyn, is lead-free and highly recyclable.

“What we do is we get the brass in really long, 12 foot by 3 foot lengths,” Biewald says, referring to one of the early steps of the cover-making process. “Then we cut that down on a saw into pieces approximately the size of the case.”

Schipper primarily focuses on the high-concept mechanics of the case and Biewald focuses on the artwork engravings on the backs of the cases. They are involved in every step of the process from design to prototype to the final, hand-finished product.

The backbone, upon which their company is based, is centered on low volume and high quality. They are constantly redesigning and improving their concepts as they stay on top of Apple’s new releases.

Biewald discussed some influences behind the signature look of their phones.

“When the design is simple and it is more about the quality and materials,” Biewald says. “Old nautical stuff, boats, and old clocks influence us---that is where the wood element comes in.”

Schipper’s personal appreciation for cases as an art form is rooted in history. He admires cases made for bibles, weaponry and musical instruments that he has seen at the Metropolitan Museum of Art.

“In the modern world the iPhone is that sort of precious object,” he says. “We need the same sort of precious case around this precious object that we use and need and are so attached to every day.”

Resources:

Also in this Issue:

- Rodin Museum: The Reality of One Man's Dream

- Earthy Persuasions in Copper: Lost Marbles Jewelry

- Brass Pocket Sculpture

- Trudi Gilliam: Mixed-Media Sculptures That Reflect Natural And Timeless Beauty

- Sotheby's Offered Magnificent Ritual Bronzes from the Collection of Julius Eberhardt