Cold working of copper and copper alloys, by rolling or other methods, will increase both tensile strength and yield strength in a very predictable manner. Most copper alloys are produced to a series of cold-rolled tempers with a tensile strength range unique to each alloy and temper designation. For this reason, there are considerably fewer variations in cold-rolled tempers than in annealed tempers. The common cold-rolled temper names and designations are:

Annealed

Oxx

Quarter Hard

H01

Three Quarter Hard

H03

Extra Hard

H05

Eighth Hard

H00

Half Hard

H02

Hard

H04

Spring

H06

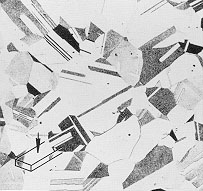

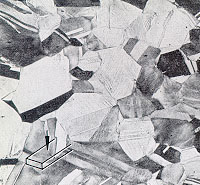

Metal Handbook, 8th Edition, Vol 7, Atlas of Microstructures of Industrial Alloys, edited by Taylor Lyman, (1972), ASM International, Materials Park, OH 44073-0002 (formerly American Society for Metals, Metals Park, OH 44073), p 283 (fig. 2333,2336,2339), p 284 (fig. 2342, 2345, 2348), p. 285 (fig 2351, 2354, 2357).

Most, but not all, alloys are rolled to meet specific standard tensile strengths for each of these tempers. Alloy C26000 will have the following nominal tensile strengths for each temper listed in Table 2.

| Rolled Temper | Nominal Reduction, % | Tensile Strength ksi | Yield Strength (0.5% Ext.) ksi | Elongation in 2.0 inches, % |

|---|---|---|---|---|

| H01 ¼ Hard | 11 | 54 | 40 | 43 |

| H02 ½ Hard | 21 | 62 | 50 | 23 |

| H04 Hard | 37 | 76 | 60 | 8 |

| H06 Extra Hard | 50 | 86 | 62 | 5 |

| H08 Spring | 60 | 94 | 62 | 3 |

A complete listing of temper designations and descriptions for copper and copper alloys cane found in ASTM B601 Standard Practice for Temper Designations for Copper and Copper Alloys-Wrought and Cast. Additional information on physical properties and cold-rolled tempers is available in data sheets from material suppliers, ASM Metals Handbook, Volume 2.