Photo ©1998 AMP INC.

Photo ©1998 AMP INC.Pure copper has poor stress relaxation resistance. Adding different elements to copper produces alloys with different combinations of strength, conductivity, formability-and stress relaxation resistance. Some alloying elements affect stress relaxation more than others. From the point of view of strengthening mechanism there are three categories of copper alloys for connector applications: solid solution-strengthened, dispersion-strengthened and precipitation-hardened. In addition, all three types are affected by cold deformation, although in somewhat different ways. The stress relaxation behavior of alloys tends to be related to the strengthening mechanism.

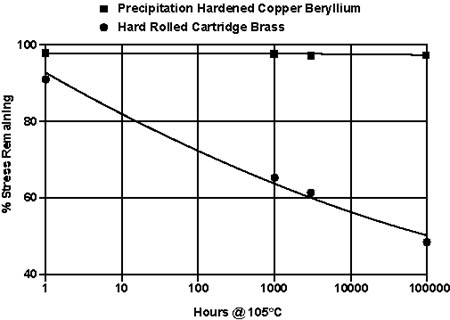

Cold deformation provides significant strength increases in almost all alloys. Unfortunately, the deformation processes that provide the strengthening are typically unstable and can be negated with time at temperatures high enough for reasonably rapid atom movement. If times are long these temperatures can be quite low and of the order of the typical operating temperatures of many classes of connectors. To illustrate this point, the following schematic figure compares the behavior of copper beryllium, which is strengthened by a precipitation heat treatment, to cartridge brass strengthened by cold rolling.

Figure 2. Strengthening Mechanism Affects Stress Relaxation

Figure 2. Strengthening Mechanism Affects Stress RelaxationA solid solution alloy such as cartridge brass would have quite good resistance to stress relaxation in the annealed condition and consequently is well suited to applications involving low contact forces. However, the limited strength available in the annealed condition requires these alloys to be cold-worked to provide the intermediate strength often required in more demanding applications. In the cold-worked condition these alloys lose strength (expressed as the % remaining stress compared to the initial stress) quite rapidly with time.

Dispersion-strengthened alloys are, by their nature, more resistance to loss of strength over time. However, they are also capable of only intermediate strength levels. If the contact design will allow the use of intermediate strength, but requires the ability to survive long times at elevated temperatures, then these alloys should be considered, especially if high electrical conductivity is important.

Precipitation-strengthened alloys may also use cold work to increase strength, but the major contribution to their strength is a thermal treatment, usually performed as the final operation (that is, after any significant cold work) and at a temperature which is well above the operating temperature of any connector. This processing provides a relatively stable metal structure which tends to resist changes with time at lower temperatures. One other point worth noting: the precipitation hardenable alloys are used in two ways. When the cold-worked strip is formed into the final contact and the contact is subsequently precipitation-hardened, the full benefit of the thermal treatment is realized. However, if the strip is purchased in the mill-hardened condition and then formed, there will be some residual cold work. This has a theoretical adverse effect on the stress relaxation resistance of the contact, although the significance of the effect is difficult to measure and may be quite small.