Electric Vehicles

Copper Applications in Electrical

Impact of Electric Vehicles on Copper | Electric Vehicles and the Environment | Electric Vehicle Infrastructure | Are Electric Vehicles Really Clean? | Hybrid Electric Vehicles | Fuel Cells | Buses | Additional Web Sites

Electric and hybrid electric vehicles have reached a new level of development with introductions by Chrysler, Ford, General Motors, Honda and Toyota. Although a large market has not yet appeared, these manufacturers have invested significant effort and capital in development and testing and it appears EVs and hybrid EVs will be coming onto the market in significant numbers. Because an electric motor is used as the primary propulsion source, these vehicles will have a much higher copper content than a conventional vehicle which currently averages about 55 pounds of copper and copper alloys.

Impact of Electric Vehicles on Copper

EVs have undergone a tremendous change since the first efforts of the Copper Development Association. In the early seventies Don Miner, in the Detroit CDA office, assisted with the manufacture and installation of a custom built electric van for the city of Birmingham, MI. Components for EVs are now mass produced by major manufacturers intent on gaining market share in this dynamic industry. At this time an EV will use, on average, as much copper as a similar vehicle with an internal combustion engine. Most of the copper used for non-electrical functions is eliminated, such as thermal components and alloys in cast aluminum. However, the motor and increased electrical functions more than double the amount of copper used for wiring and connectors. Most EVs are using 250 - 350 volts in their power source, which means all connectors and wiring attached to the batteries, inverters and power controllers must be increased in size to handle the higher voltages and currents.

Yazaki and United Technologies displayed wiring components at the EVS-14 Conference held during December of 1997, in Orlando, Florida. They manufacture these components for both EVs and hybrid vehicles. The engineers at these companies must be concerned with current carrying capacity, thermal properties, corrosion resistance and, of course, cost. They work hard at insuring that the components perform well in specific vehicles and this means using more copper. UTA confirmed that for the Electric Ford Ranger, the wire harness and connectors contain approximately twice as much copper as the conventional Ford Ranger harness.

Yazaki and United Technologies displayed wiring components at the EVS-14 Conference held during December of 1997, in Orlando, Florida. They manufacture these components for both EVs and hybrid vehicles. The engineers at these companies must be concerned with current carrying capacity, thermal properties, corrosion resistance and, of course, cost. They work hard at insuring that the components perform well in specific vehicles and this means using more copper. UTA confirmed that for the Electric Ford Ranger, the wire harness and connectors contain approximately twice as much copper as the conventional Ford Ranger harness.

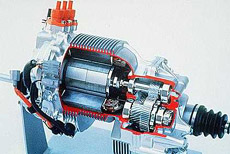

The principle behind all EVs and hybrids (as opposed to alternative fuel vehicles) is to drive the wheels with electric motors. Whether one motor or two are used, there is a significant increase in the use of copper magnet wire, approximately 12 - 25 pounds per vehicles. CDA has a major project for increasing the efficiency of motors through the use of cast copper motor rotor bars. AC induction motors are the preferred technology, for EVs, at this time and this requires the use of an inverter to change the DC from the batteries to AC for the motor. It is estimated that an inverter will require an additional 8 - 10 pounds of copper and copper alloys. Additional increased copper content results from a number of accessories being electric instead of hydraulic. Power steering and braking are achieved electrically. The efficiency and performance of these two technologies make them candidates for installation on internal combustion vehicles in the near future. Heating and air conditioning are also achieved electrically and in some cases with a heat pump.

The principle behind all EVs and hybrids (as opposed to alternative fuel vehicles) is to drive the wheels with electric motors. Whether one motor or two are used, there is a significant increase in the use of copper magnet wire, approximately 12 - 25 pounds per vehicles. CDA has a major project for increasing the efficiency of motors through the use of cast copper motor rotor bars. AC induction motors are the preferred technology, for EVs, at this time and this requires the use of an inverter to change the DC from the batteries to AC for the motor. It is estimated that an inverter will require an additional 8 - 10 pounds of copper and copper alloys. Additional increased copper content results from a number of accessories being electric instead of hydraulic. Power steering and braking are achieved electrically. The efficiency and performance of these two technologies make them candidates for installation on internal combustion vehicles in the near future. Heating and air conditioning are also achieved electrically and in some cases with a heat pump.

EVs and even hybrid EVs will use approximately twice as much copper as a conventional vehicle and this will provide the added advantage of excellent recyclability when the vehicle is removed from service.

Electric Vehicles and the Environment

According to the U.S. Environmental Protection Agency (EPA), vehicle emissions currently contribute between one third and one half of the total U.S. atmospheric burden of three major pollutants: carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC). Their impact is even greater in many U.S. urban areas.

EVs produce much lower emissions than even the cleanest internal-combustion engine vehicles, even when emissions associated with electricity production are taken into account. EVs produce no direct emissions, in contrast to gasoline-powered vehicles, which emit combustion pollutants from the tailpipe as well as evaporated hydrocarbons from the fuel system. Moreover, EVs are cleaner than internal-combustion engine vehicles throughout their useful vehicle life. Because EVs don't burn fuel, there can be no degradation or failure of emissions-control systems. Thus, unlike conventional vehicles, which tend to pollute much more as they get older, EVs maintain their negligible emission rates over time.

An electric vehicle is the closest thing to a nonpolluting transportation medium. The only adverse effects on the environment would be linked to the generation of electricity to charge their batteries and, possibly, to disposal of the batteries (although recycling may dispel this concern). Although the initial price of electric cars will likely be higher than the price of internal combustion engine vehicles, electric vehicles should have lower overall life-cycle costs. Inadequate batteries, at present, are the only significant obstacles to widespread use.

Electric Vehicle Infrastructure

Currently, both conductive and inductive charging are commercially available for EV's. As more electric vehicles appear on the roads, the market will determine which method is most advantageous, but for now both systems are used. Edison Electric has been selected by Toyota and G.M. for installation of inductive charging systems.

Currently, both conductive and inductive charging are commercially available for EV's. As more electric vehicles appear on the roads, the market will determine which method is most advantageous, but for now both systems are used. Edison Electric has been selected by Toyota and G.M. for installation of inductive charging systems.

They have installed over 365 charging stations in Southern California and Arizona and have plans for 100 per year for the next three years. Electric Vehicle Infrastructure, Inc. has installed over 500 conductive charging stations and recently announced a new line of conductive charging products (ICS-200 PowerStation) that has received a UL listing. The charging units themselves do not contain particularly large amounts of copper, approximately 2 - 5 pounds per charger. The total infrastructure, including wiring, meters and controllers could use significant amounts of copper as EV's become more common. In addition to the efforts of Edison Electric and others in California and Arizona, initiatives are underway in Massachusetts, New Jersey and New York to install charging infrastructure.

Today's charging technology includes conductive and inductive charging systems. Both systems will require electronics off-board the vehicle to provide communications and diagnostic capabilities required by recommended practices under development. In addition, there are three standardized charging levels:

Level 1: charging can be done from a standard, grounded 120V, 3-prong outlet available in all homes;

Level 2: charging is at 240V, 40 amp charging station with special consumer features to make it easy and convenient to plug in and charge EVs at home or at an EV charging station;

Level 3: a high-powered charging "fast charge" technology currently under development that will provide a charge in less than 15 minutes.

Conductive charging systems use a plug and cord system that can vary by the type of connector used and the level of voltage and current. The charger can be located either onboard (built into the vehicle) or off-board (separate from the vehicle) depending on the design of the conductive system.

Inductive charging systems use a cord and paddle, called an inductive coupler, that transfers energy to the vehicle by means of magnetic induction.

Inductive charging systems use a cord and paddle, called an inductive coupler, that transfers energy to the vehicle by means of magnetic induction.

When the paddle is inserted into the charge port, electrical power is passed through an electromagnetic field between the paddle and the charge port. This inductive design replaces the common plug and socket used in conductive charging. The incoming AC power is converted to DC and stored in the vehicle's batteries.

Are Electric Vehicles Really Clean?

An electric car produces no exhaust, but if the electricity to run the car came from a power plant that burned a fuel, that plant did produce air pollutants. We have to look at the whole system. In the same way, for gasoline powered cars we must include pollution from gas stations, refineries, etc. Which is greater, the amount of pollution produced by a car with an internal combustion engine engine going a certain number of miles, or the amount of pollution produced by an electric car going the same number of miles, plus the power plant?

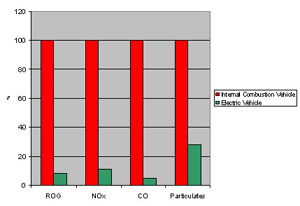

Many researchers have studied this problem, and the general conclusion is that, including the power plant emissions, the electric vehicle is much less polluting. How much cleaner it is depends on what energy source the power plant uses, coal being the dirtiest.

The graph below shows estimates* of the amounts of pollutant an electric vehicle in San Francisco would produce per mile in the year 2011. The values are listed as a percentage of the estimated pollution from a gasoline powered car that met California's Ultra-Low Emissions Vehicle standard (few of today's cars meet the ULEV standard.) Because internal combustion engine (ICE) cars tend to become dirtier as they get older, the pollutants per mile figure for the ICE are averages over the first ten years of the car's life. For electric vehicles, emissions from all power plants that supply San Francisco are included, even plants hundreds of miles away.

(Graph provided courtesy of EV Media, Santa Monica, CA. A source of marketing and education tools for the electric vehicle industry)

(Graph provided courtesy of EV Media, Santa Monica, CA. A source of marketing and education tools for the electric vehicle industry)This comparison doesn't include pollution from producing oil, mining coal or junking the cars, but the parts that have been omitted produce a very small percentage of the total emissions.

Tailpipe emissions are not the only way a car can pollute: oil and coolant can leak, and tires and brakes make dust as they wear.

* Data from EV Emissions Benefits in California, Technical Brief RP2882. (Palo Alto, CA: Electric Power Research Institute, May 1994). The report's authors believe the results to be conservative because they do not take into account emissions from ICE cars due to lack of maintenance, driving cycles other than that in the test (e.g., more waiting at stop lights or in traffic jams), or the owners' tampering with pollution control equipment - all factors that do not apply to EVs.

Hybrid Electric Vehicles

A Hybrid Electric Vehicle (HEV) is a vehicle that has two sources of motive energy. The hybrid system currently in production uses a gasoline engine in combination with batteries and an electric motor. The impact of HEVs on copper is an increase of 70 - 100% over a conventional ICE vehicle.

Toyota recently unveiled the Prius Hybrid EV for sale in Japan. This vehicle uses the Toyota Hybrid System that combines a high efficiency gasoline engine with electric motors to maximize energy efficiency and reduce emissions. Energy-saving features include automatic engine shutdown when the vehicle is stopped and regenerative braking that converts kinetic energy into electricity to charge the battery. According to news sources, Toyota received 2,000 orders for the Prius the first day it went on sale in Japan. Company officials have indicated that there are plans to introduce the Prius for sale in the United States no later than 2000.

Previous hybrid systems were generally classified as either parallel or series type. The Toyota system is based on the parallel type but to optimize the engine's operation, it includes a system that enables series-like operation through the use of a generator and a motor that are independent of each other. Under high speed and heavy loads, both the engine and motor drive the wheels.

At the Detroit International Auto Show, Chrysler displayed its newest concept car. The Dodge Intrepid ESX2 is a diesel electric hybrid that gets 70 miles per gallon and emits 56 percent less carbon dioxide.

HEVs have several advantages over traditional internal combustion engine (ICE) vehicles, such as:

- Fuel efficiency is greatly increased, while emissions are greatly decreased.

- Engine is sized to average load, not peak load, which reduces the weight of the engine.

- Regenerative braking can be used, which helps minimize the energy lost when driving.

- HEVs can be operated using alternative fuels.

The auto manufacturers' goal is to achieve these benefits with no appreciable loss in vehicle performance, range, and safety. With two drive trains (an ICE running on gasoline or alternative fuels and a battery-driven electric drive train) the HEV is able to operate approximately two times more efficiently than traditional ICE vehicles.

Fuel Cells

An alternative to batteries for supplying electrical power for a vehicle is fuel cells. A fuel cell powered vehicle uses the electrochemical reaction of combining hydrogen and oxygen to produce electricity. A traction motor is used as the primary propulsion unit so that the impact on copper is very favorable, resulting in an increase of 70 - 100% in copper content when compared to a standard ICE vehicle.

Fuel cells are even more benign to the environment than battery powered Evs.

It is possible to operate fuel cells on pure hydrogen or a variety of hydrogen-rich fuels, such as methanol, ethanol, natural gas or even gasoline. Like batteries, fuel cells are approximately twice as efficient as gasoline-fueled internal-combustion engines and can provide zero emissions. Fuel cell vehicles utilize an external fuel supply, and can therefore match or better the driving range of today's cars. The potential of fuel cell technologies to revolutionize the automobile industry has been recognized by major automobile manufacturers. All three domestic manufacturers are developing prototype fuel cell passenger vehicles. Ford, Daimler-Benz and Ballard announced in December that they had formed a global Alliance to develop fuel cell technology for future vehicles. According to Ford Chairman Alex Trotman, "Ford sees this partnership as a natural complement to the talent, skills and technology among the three companies. We have been working on the technology to support fuel cell vehicles for many years and view fuel cells as one of the most important technologies for the 21st century."

A number of fuel cell buses are already in operation and targeted for commercialization in about five years.

Buses

Electric and hybrid buses are also proving to be a cleaner means of transportation particularly in cities where smog is a constant health hazard. The city of Santa Barbara has one of the largest fleets of electric buses in the U.S. with 14 in service. According to city officials the annual number of riders, on the electric buses, has increased from 200,000 in 1991 to over 1 million in 1997. They state that it is now common that a rider will pass up a diesel bus to wait for the next electric. The buses require minimal maintenance, and most importantly, reduce the amount of particulate matter that enters the atmosphere. In addition to Santa Barbara, electric bus fleets are operating in Chattanooga, Tenn. and Anderson, Ind.

Additional Web Sites

| Chrysler | http://www.chrysler.com |

|---|---|

| Ford | http://www.ford.com |

| General Motors | http://www.gm.com/ |

| Honda | http://www.honda.com |

| Nissan | http://www.nissanusa.com |

| Toyota | http://www.toyota.com/ |

| Electric Drive Transportation Association | http://electricdrive.org/ |

| Electric Power Research Institute | http://www.epri.com |

| Arthur D. Little (Fuel Cells) | http://www.arthurdlittle.com |

Contact:

Robert D. Weed

Vice President, Rod, Bar & Mechanical Wire

Automotive and Building Construction

P.O. Box 2504

Birmingham, MI 48012

Tel: 248-642-6980

Fax: 248-642-4770

Email

Also in this Issue:

- Electric Vehicles

- New Research Program Focuses on Improvements for the 21st Century

- A Discussion of Future Trends and Their Influences on the Copper Strip, Sheet and Plate Industry Part 2 of 2

- A Discussion of Future Trends and Their Influences on the Copper Strip, Sheet and Plate Industry Part 1 of 2

- Copper Motor Rotors: Application of High Temperature Mold Materials to Die Cast the Copper Motor

- CDA Backs DX Geothermal Heat Pump R&D