On December 19, 2007, President George W. Bush signed into law the Energy Independence and Security Act of 2007 (P.L. 110-140). Similar to its predecessors, the Energy Policy Act of 1992 (EPAct '92) and the Energy Policy Act of 2005 (EPAct '05), and related pieces of legislation dating back to the 1970s, the 2007 Act aims to restructure and reduce, or at least slow the rate of growth in America's energy consumption. It also mandates higher automotive fuel economy, promotes use of biofuels and alternative energy sources, raises efficiency standards for public buildings, equipment and appliances, and provides public funding for a host of energy-related issues.

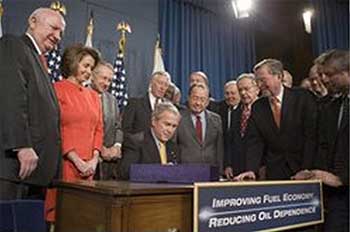

President George W. Bush signs the Energy Independence and Security Act of 2007, thereby raising motor efficiency standards for more applications than had been addressed by previous energy legislation. The new Act will benefit users by lowering energy costs while at the same time reducing the consumption of fossil fuels.

President George W. Bush signs the Energy Independence and Security Act of 2007, thereby raising motor efficiency standards for more applications than had been addressed by previous energy legislation. The new Act will benefit users by lowering energy costs while at the same time reducing the consumption of fossil fuels.Perhaps more importantly for motor users the 2007 version increases the mandated efficiency of electric motors in commercial and industrial applications, and expands the range of motors that in question. Those provisions, contained in Title III, Section 313, represent a small section of the Act's 822 pages, however, eventually they may bring about a very large reduction in wasteful energy use.

Why? Because, as the Department of Energy, the Consortium for Energy Efficiency (CEE) and other organizations have pointed out repeatedly, electric motors account for nearly 50 percent of total U.S. energy use, and two-thirds of energy used in industrial settings. It follows then, that if the efficiency of those motors were raised by even a few percentage points, the savings, in kilowatt-hours and in dollars for both individual users and the nation-at-large, could be enormous.

EPActs '92 and '05, respectively, set minimum standards for motor efficiencies and mandated the use of premium-efficiency motors in Federal buildings. The new Act raises that bar and redefines - and thereby expands - the types of motors required to meet existing efficiency standards. Following are excerpts from the 2007 Energy Independence and Security Act as well as some of the benefits the new legislation will bring to motor users.

Definition of covered motors:

TITLE III - ENERGY SAVINGS THROUGH IMPROVED STANDARDS FOR APPLIANCE AND LIGHTING

SEC. 313. ELECTRIC MOTOR EFFICIENCY STANDARDS.

(a) DEFINITIONS. -Section 340( 13) of the Energy Policy and Conservation Act (42 U.S.c. 6311 (13)) is amended-

(1) by redesignating subparagraphs (B) through (H) as subparagraphs (C) through (I), respectively; and

(2) by striking 1/( 13)(A)" and all that follows through the end of subparagraph (A) and inserting the following:

1/(13) ELECTRIC MOTORS.-

I/(A) GENERAL PURPOSE ELECTRIC MOTOR (SUBTYPE 1).-

The term 'general purpose electric motor (subtype I)' means any motor that meets the definition of 'General Purpose' as established in the final rule issued by the Department of Energy entitled 'Energy Efficiency Program for Certain Commercial and Industrial Equipment: Test Procedures, Labeling, and Certification Requirements for Electric Motors' (10 CFR 431), as in effect on the date of enactment of the Energy Independence and Security Act of 2007.

I/(B) GENERAL PURPOSE ELECTRIC MOTOR (SUBTYPE 11).-

The term 'general purpose electric motor (subtype II)'

means motors incorporating the design elements of a general purpose electric motor (subtype I) that are configured

as 1 of the following:

I/(i) A U-Frame Motor. I/(ii) A Design C Motor.

I/(iii) A close-coupled pump motor.

"(iv) A Footless motor.

\ "(v) A vertical solid shaft normal thrust motor (as tested in a horizontal configuration).

"(vi) An 8-pole motor (900 rpm).

"(vii) A poly-phase motor with voltage of not more than 600 volts (other than 230 or 460 volts.".

As you can see, the term "general-purpose motors" has been expanded to include both the motors we generally think of in this regard (here called Subtype I), and another group of motor types (defined as Subtype II) to which neither the high-efficiency standards of EPAct '92 nor the NEMA Premium™ standards called out in EPAct '05 previously applied.

Mandated Standards:

(b) STANDARDS.-

(1) AMENDMENTS.

-Section 342(b) of the Energy Policy and Conservation Act (42 U.S.c. 6313(b)) is amended-

(A) by redesignating paragraphs (2) and (3) as paragraphs (3) and (4), respectively; and

(B) by inserting after paragraph (1) the following: "(2) ELECTRIC MOTORS.

-H. R. 6-78

"(A) GENERAL PURPOSE ELECTRIC MOTORS (SUBTYPE I ).-

Except as provided in subparagraph (B), each general purpose electric motor (subtype I) with a power rating of 1 horsepower or greater, but not greater than 200 horsepower, manufactured (alone or as a component of another piece of equipment) after the 3-year period beginning on the date of enactment of the Energy Independence and Security Act of 2007, shall have a nominal full load efficiency that is not less than as defined in NEMA MG-1 (2006) Table 12-12.

Table 12-12 of NEMA MG-1 (2006) defines NEMA Premium efficiency standards for motors up to 500 hp. Under the Energy Independence and Security Act of 2007, the minimum nominal full-load efficiency standards for "traditional" general-purpose motors, i.e., those running at 1200, 1800 and 3600 rpm with power ratings up to 200 hp, are raised to NEMA Premium values from the previously mandated EPAct '92 standards (for the so-called "EPAct motors"). In essence, NEMA Premium efficiency minimums replace EPAct '92 levels as the baseline for these motors.

Another noteworthy change pertains to general-purpose motors. Now, under the 2007 Act, they are governed by the Act's standards whether they are purchased "alone or as a component of another piece of equipment." In other words, applicable OEM-supplied motors are now included under NEMA Premium standards. Previously, equipment buyers often had to insist that the machines they purchased were powered by energy-efficient motors.

The one exception to this provision is that fire pump (sprinkler system) motor minimum efficiencies are raised only to the EPAct '92 standard. Fire pump motors, however, are seldom in operation, and, therefore, consume very little energy over their service lives.

Next:

"C) GENERAL PURPOSE ELECTRIC MOTORS (SUBTYPE II).

-Each general purpose electric motor (subtype II) with a power rating of 1 horsepower or greater, but not greater than 200 horsepower, manufactured (alone or as a component of another piece of equipment) after the 3-year period beginning on the date of enactment of the Energy Independence . and Security Act of 2007, shall have a nominal full load efficiency that is not less than as defined in NEMA MG-1 (2006) Table 12-11.

Table 12-11 of NEMA MG-1 (2006) sets minimum efficiency standards for EPAct motors. As mentioned earlier, the "Subtype II" motors as defined in the 2007 Act had previously been excluded from energy legislation entirely, meaning that they could be sold lawfully as old-style, standard-efficiency models. That's no longer the case.

Finally, "(D) NEMA DESIGN B~ GENERAL PURPOSE ELECTRIC MOTORS.-Each NEMA Design B, general purpose electric motor with a power rating of more than 200 horsepower, but not greater than 500 horsepower, manufactured (alone or as a component of another piece of equipment) after the 3-year period beginning on the date of enactment of the Energy Independence and Security Act of 2007, shall have a nominal full load efficiency that is not less than as defined in NEMA MG-1 (2006) Table 12-11."

This section of the 2007 Act extends EPAct '92 efficiency requirements to motors between 201 and 500 hp. A ccording to the CEE, motors larger than 200 hp account for 45 percent of industrial motor energy use, despite the fact that they account for only one percent of units in the entire manufacturing inventory. Furthermore, CEE reports that approximately 80 percent of the motors in the industrial inventory are pre-EPAct '92 models. In addition, the average duty cycle for these motors is 6,100 hours per year. CEE estimates that these motors represent a potential energy savings of 7.7 billion kWh annually.1

The 2007 Act takes effect on December 19, 2010. Until then, it is lawful to purchase and install EPAct-level general purpose motors and standard-efficiency GP motors for those models to which EPAct '92 doesn't apply. On the other hand, if your motors operate at high duty cycles and/or they face high or rising utility rates, you will fare better by selecting NEMA Premium motors before they are mandated. It is wise to understand that better motors will return your investment by the time the new Act takes effect. Work smarter by upgrading sooner rather than later.