There are many players in the worldwide effort of auto manufacturers and suppliers to achieve efficiency, reduced cost, decreased dependency on oil, and lower emissions with vehicle electrification. Each has a viewpoint and approach that reflects company values, positioning in the marketplace, and technological focus.

As batteries improve to increase energy storage and reduce costs, electric vehicles are ever closer to becoming commonly found in family garages. Limitations include a short driving range before recharging is needed, long recharging times, and the struggle to arrive at electric vehicles that will be, not only accepted, but embraced by the car-buying public.

Engineering services provider AVL, with headquarters in Graz, Austria, has been a force behind some of the most exciting innovations used by automotive OEMs and suppliers alike, including power train systems, electric motors, batteries, and control systems. AVL provides design, development and validation capabilities for the entire electrified power train, including the pure battery electric vehicle, the range extender and plug-ins as well as mild- and full-hybrid vehicles.

Jerry Klarr, Director of Hybrid Programs at AVL, recently took time out of his schedule to discuss the company’s role in vehicle electrification. He’s enthusiastic about their efforts to help move the industry forward. “What we focus on is overall system optimization,” he says. “We work with supply base to help them understand how to put their systems into vehicles and the OEMs to help define what kinds of components are required.” The company works in three areas – engineering, testing and simulation – providing services to both manufacturers and suppliers.

The Turbohybrid

Among the advancements that AVL is noted for is the turbohybrid, which combines a turbocharged gasoline engine with an electric motor, increasing fuel economy as well as performance. “Engines like to operate at their most efficient point for both economy and performance,” says Klarr. “A turbo allows you to downsize the engine so when you don’t need the performance, you can use less displacement get your fuel efficiency Then, when you need the power, the turbo comes into play. If we put a hybrid system on there, the turbo actually generates more energy than needed. The turbohybrid takes that unused energy that’s generated by the turbo system and actually uses it to help charge the system, recovering energy into the battery pack.”

Public acceptance of electric vehicles and hybrids depends in large part on the driving experience itself. AVL’s turbohybrid generates higher and mid-range power, giving drivers the “fun factor,” while improving fuel efficiency at those higher speeds. AVL hopes that this kind of thinking will help drivers adopt and embrace newer technologies.

In early 2009, BMW tested a demo 3-Series vehicle, a 1.6-liter AVL turbohybrid prototype that delivered a 10% reduction in fuel consumption while boosting performance. The concept car debuted to largely positive reviews.

The Range Extender

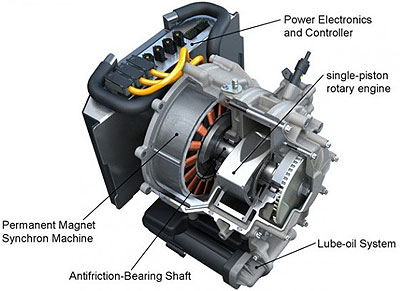

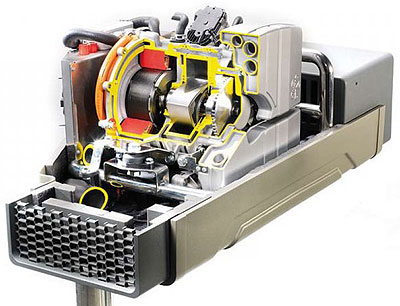

An even more recent AVL innovation is the range extender with a Wankel engine that achieves optimal energy efficiency and performance. The range extender is an autonomous auxiliary power unit added to pure electric drive vehicles to extend the operational range beyond that of a purely electric mode. “The range extender was a concept power pack that was basically very compact, high energy and high density with light weight,” says Klarr. “We’ve brought it to various shows and have gotten some strong interest.”

While AVL is not the only company working with range extenders, the challenge is to utilize them in new, more efficient ways. Klarr says, “What we do is integrate them into applications and systems so that they’re more efficient than what we’ve seen on other applications.”

Energy Storage

In April, AVL displayed some of their innovative work with batteries at the SAE 2010 World Congress show.

Photo courtesy of AVL

AVL is currently working with battery companies including Dow Kokam, Johnson Controls, A123 and Compact Power. “We’ve developed several battery simulation tools using a thermal type of modeling as well as overall system modeling,” Klarr says. The company is also developing various battery testing systems.

Regenerative braking is another energy storage system that is being adapted for both hybrid and pure electric vehicles. “Everybody tries to do as much regen as they can, because it is free energy, so to speak,” says Klarr. “As you go from mild to full hybrid to pure electric you can gather more and more regeneration.”

The issue, again, is driver acceptance. “You’ve always got to think of the customer and how they’re going to react,” says Klarr. “They expect a certain rate of deceleration and all of a sudden they get excessive deceleration. We’ve found that, as people are using hybrids, until they get used to them, they’re sensing things that they hadn’t sensed on conventional systems before. So there’s a little bit of a learning curve there.”

Copper’s Role

Klarr says that copper will continue to play a substantial role in the automotive industry as electrification of vehicles expands. “It’s still is one of the preferred elements to use in both the battery and the high voltage systems because of its conductivity capabilities, its resistance to oxidation and its malleability, so it’s still a preferred solution,” he says. “There’s also quite a lot of copper coming into play in the high voltage wiring systems and in some of the batteries.”

Another area in which copper will likely play a substantial role is in charging systems that will be used to keep vehicles running. “Along with the hybrid and the electrification of vehicles is the infrastructure. There are going to be charging stations built that are almost certainly going to use significant amounts of copper,” Klarr notes.

Looking to the Future

“Everybody has an opinion about what’s going to happen in the automotive industry in the next three, five or ten years,” says Klarr. “I think most people are thinking the current penetration of hybrids is expected to go to maybe 9 or 10 percent in 2015, and that’s the kind of number that we’re looking at as well.”

Meeting efficiency standards, power needs, and affordability at the same time is the challenge. Klarr says that the best solutions will come from system optimization and collaboration of OEM’s and suppliers. “I always said if it was easy you’d see 100 more companies out there.”

The AVL Turbo Hybrid

The AVL Turbo Hybrid The AVL Range Extender

The AVL Range Extender