In 1886, Miss Liberty was:

- Tallest iron structure ever erected.

- Largest concrete pour ever made.

- Used one of the first passenger elevators.

- And, contained one of the first indoor lighting systems ever installed.

- Significantly, it was the largest use of copper in a single structure at that time.

Okay, now without embarrassment, let's take a close look at the First Lady's figure:

- Height: 151' 5" (on a 154' base)

- Weight: 450,000 pounds

- Eye set: 2' 6" (dist. between eyes)

- Ear set: 10' (dist. between ears)

- Nose: 4' 6"

- Mouth: 3'

- Hand: 16'

- Finger: 8' (index)

- And, oh yes, … her bust is a perfect 36 … feet.

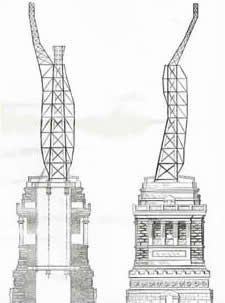

To support his colossal sculpture, Bartholdi called upon the structural engineering skills of Gustave Eiffel, who designed the skeleton for its skin of copper. This was sort of a trial run for Eiffel's Tower, which was to come about five years later.

Gustave Eiffel

Gustave EiffelThe Lady's skeleton is made from about 250,000 lbs of puddled iron. It's spine is a pylon containing a double-helix stairwell. Four legs support the pylon, each connected by nine levels of horizontal struts and diagonal cross braces.

Framework: 250,000 lbs; 1,800 puddled-iron bars (framework and armature)

Framework: 250,000 lbs; 1,800 puddled-iron bars (framework and armature)There is also a secondary frame, or armature, that conforms to the outer contour of the statue. The armature consists of about a mile's worth of puddled-iron bars, more than 1300 of them, 2" wide by 5/8" thick and weighing about 20 lbs each.

Armature: 1,350 puddled-iron bars; 4' x 2" x 5/8"; 20 lbs, each

Armature: 1,350 puddled-iron bars; 4' x 2" x 5/8"; 20 lbs, eachSome 80 tons of copper sheet, originally about a quarter-inch thick, were cut into 300 odd pieces and then hand hammered - a process called repoussé. The hammering reduced them to about 3/32nds of an inch thick.

Skin: 300 sheets of copper; ~3/32" thick; 160,000 lbs

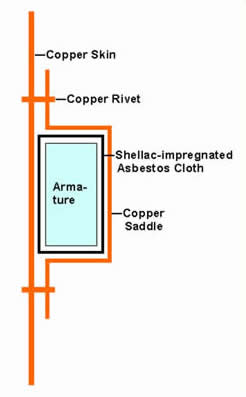

Skin: 300 sheets of copper; ~3/32" thick; 160,000 lbsNow, here's where the neat part comes in. The copper skin sections are attached to the armature by 1500 U-shaped copper saddles, using some 300,000 copper rivets. Now, Eiffel knew about Galvanic corrosion between the dissimilar metals - copper and steel. The first consideration, apparently, was to let the American's worry about that when it happens.

That was quickly followed by discussion of using a red-lead barrier and cloth-covered copper plates that would go between the copper skin and the iron armature.

Saddles: 1,500, copper; Rivets: 300,000 copper

Saddles: 1,500, copper; Rivets: 300,000 copperUltimately, it was the Americans who came up with the barrier system finally used when the stature was reassembled. They isolated the junction of the copper and iron with a layer of shellac-impregnated asbestos cloth.

The saddle design was ingenious. Copper and Iron expand and contract at different rates. So, the free movement of the separate metals allowed them to accommodate the changes in temperature as well as other weather conditions.

Saddle Detail

Saddle Detail