The Driving Force of Hybrid Vehicles

Copper continues to play an important role in new automotive technology

It started as an engineering concept at the turn of the 21st century - gas-electric "hybrid" dream cars displayed at auto shows to gauge public reaction and market potential. But within just a few years (a wink of time in vehicle development terms), hybrids have evolved into one of today's most important automotive trends.

Numerous components have come into play in the advancement of this technology, but one element in particular - copper - has been indispensible in helping to propel the growth of hybrid vehicles.

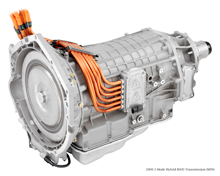

Inside this 2009 Two-Mode hybrid RWD transmission, you will find two heavily copper-intensive motors.

Inside this 2009 Two-Mode hybrid RWD transmission, you will find two heavily copper-intensive motors.

Copyright © GM Corp.

High-resolution version of this photo.

According to General Motors Chief Engineer Tim Grewe, "Copper has two important roles in hybrids: It runs the electricity, so you have large amounts of copper in the motor and battery, and, more importantly, the copper technology is making hybrids viable commercially."

Vehicles, along with their electronic components, must be made robust enough to take years and miles of often hard driving, unlike electronic products that remain stationary throughout their lifetimes. Grewe pointed out that for many hybrid automotive components, including electric motors and the electronics and circuit boards that regulate them, manufacturers like GM turn to "high ounce," or heavy weight, copper laminates.

"Using 15-ounce copper allows us to mass produce systems, which is very cost-effective," Grewe said. Now that production lines are up and running, General Motors plans to increase its present number of hybrid models from six to 15 by 2012.

GM's Two-Mode Hybrid System is one example of how hybrids are progressing. It includes two powerful copper-wound electric motors built into the drivetrain, which allows even large vehicles, like SUVs or pickup trucks, to operate at 30 mph using electric power alone. As speed increases, the vehicle's conventional gas engine takes over, but supplemental electric power continues to improve fuel economy while recharging the batteries. This system was recently honored with a prestigious 2008 Technology of the Year industry award.

Other hybrid auto manufacturers have not been sitting idle. At this year's Detroit Auto Show in January, Ford Motor Company introduced a new Fusion hybrid mid-size sedan that trumps its rivals by offering an equivalent 39 miles per gallon (mpg) running in electric-only mode at speeds up to 47 mph. Like GM, Ford is pursuing a number of alternative-propulsion vehicles still in the development stages. Another manufacturer, Honda, is anticipating demand and introducing a second hybrid model, the Insight, in April.

Meanwhile, Toyota, an early leader in hybrid technology, unveiled a third-generation Prius for 2010 that will get up to 50 mpg. More than one million models of the Prius have been sold worldwide since the car's introduction in 1997.

Wade Hoyt, Toyota's public affairs manager in New York, also noted copper's contribution to the Prius. "Copper is used for all the windings in our two electric motors, which is an important part in the hybrid synergy drive," he explained.

The Prius accounts for 75 percent of all Toyota hybrid sales. According to the Automotive News Data Center, it continues to lead the market with 241,405 cars out of a total 315,761 hybrid vehicles sold in 2008. The only company to increase its hybrid sales-almost three fold-in 2008 was General Motors, which sold 14,439 hybrids compared to 5,175 in the previous year.

Hybrid design, along with other automotive technology, has entered a period of rapid advancement, but industry insiders say that regardless of how tomorrow's vehicles evolve, copper will remain a critical component.

"The hybrid market is still relatively young," according to GM's manager of hybrid communications, Brian Corbett. "It's still growing and it's hard to say if it has exploded yet. It's a part of the market with a lot of visibility." He points out that hybrids only accounted for about 3 percent of the market in 2008, but within the next decade he foresees that percentage rising to 15 percent or higher.

"In 2000, it was just small 'image' cars," Corbett said. "They were narrow-purpose vehicles that looked a little strange. Now, in 2009 there's a much broader array of vehicles that people really want, and not just custom image cars."

The copper industry, which produces a vast array of electrical and electronic components and is therefore a key supplier to the automotive manufacturers, has been a major proponent of hybrid development.

"Increased market shares for hybrid vehicles tend to have a positive impact on copper," says Robert Weed, vice president for the Copper Development Association (CDA) in Detroit. "Copper is still the most efficient and most preferred material when it comes to conducting electricity."

Innovations like hybrids, and the all-electric cars now on the drawing boards, typically require novel engineering solutions, and for products that are copper-intensive in design, organizations like CDA often help to facilitate production. The association was instrumental in developing the copper motor rotor, a breakthrough electrical component used to power what is perhaps the "hottest" vehicle innovation today, the all-electric Tesla Roadster.

As the hybrid market continues to expand, competing technologies such as ethanol-burning cars and trucks, "clean diesels," hydrogen-powered fuel cells and all-electric vehicles are driving hard to catch up - and could even overtake hybrids in the future. Regardless of which technologies ultimately win out, copper components will be an intrinsic part of tomorrow's more efficient and environmentally friendly automobiles.

As CDA's Bob Weed observes: "Copper at the present time plays a very important role in all of the wiring systems, electrical motors and battery storage devices in our vehicles, and we expect that to continue in the years ahead." Cu