Copper Vital to World Trade

An Enduring Technology

The first underwater communications cable was laid in New York Harbor in 1842 between Governor's Island and Manhattan by Samuel Morse. Before he could tap out the first telegraph message, the cable was severed by a ship's anchor. Morse had to wait another two years before he sent his historic "What Hath God Wrought" message between Washington and Baltimore.

The first international underwater telegraph cable was laid between England and France in 1851. After four failed attempts beginning in 1857, the first successful transatlantic cable was laid in 1866 by the Great Eastern, at that time the world's largest ship. A ship of that size was needed because the continuous cable itself weighed 9,000 tons.

The first transatlantic cable to carry telephone traffic was not laid until 1956. Copper carried the first signals and remained the medium for those signals until the advent of fiber optics a decade ago.

Thousands of tons of copper are required each year to fabricate the undersea communications cables needed to conduct the ever-growing data and voice traffic between the world's trading nations. Although silica-glass fibers have supplanted copper as the signal-carrying medium (see sidebar below), there's far more copper than glass in the latest cables, some of which are thousands of miles long.

Copper plays two irreplaceable roles in today's undersea cables: enclosing and sealing the strands of glass against contaminants and carrying power to the series of electronic repeaters that amplify the signals in transoceanic cables. Shorter cables, such as the one under Lake Michigan between Kewaunee, Wisconsin, and Arcadia, Michigan, don't require repeaters.

To observe the complex process by which the cables are fabricated, Copper Topics went to Portsmouth, New Hampshire, to visit the world's largest plant devoted to their manufacture. There, Simplex Technologies Inc. assembles cables in segments up to 70 kilo meters (43.5 miles) long in a non-stop process from strands of fiberglass wrapped around a copper-clad steel wire core. Next, a mixture of pellets of two polymers, Hytrel and Nylon, are melted over the strands to hold them in place. Tensile strength is added by spiraling steel cable around the core assembly.

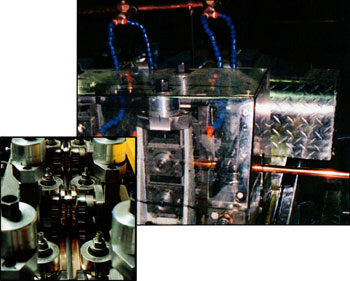

Then, copper strip, an inch or more wide and 20 mils thick, is automatically and continuously formed into a tube and welded longitudinally to wrap the cen tral fiber-optic bundle. Next, a thick layer of medium- or high-density polyethylene is applied. In cables designed for abrasive sea bottoms or shore terminals, additional steel wires are imbedded in the polyethylene layer. These heavy-duty cables are spliced to lighter cables that make up the long transoceanic runs. Simplex also applies the same protective outer layers to undersea power cables, manufactured by others, in which copper conductors carry the current.

A strip of thin copper is formed around the message-carrying core of undersea communications cable at Simplex Technologies (left). When the copper is welded tight the tube seals out contaminants (above). The copper also carries power to the repeaters required for transoceanic cables. The return path for the current is through the salty ocean.

A strip of thin copper is formed around the message-carrying core of undersea communications cable at Simplex Technologies (left). When the copper is welded tight the tube seals out contaminants (above). The copper also carries power to the repeaters required for transoceanic cables. The return path for the current is through the salty ocean.The copper in Simplex' cables is oxygen-free C10200 purchased from a number of domestic and international suppliers. The silica-glass fibers are supplied to Simplex by Lucent Technologies.

According to L. Dennis Kozlowski, CEO of Tyco International Ltd. Co., the parent company of Simplex, some 5,000 tons of copper are needed each year to fabricate the cables. Simplex, the only American maker of undersea communication cables, has several overseas competi tors. Together they fabricate the tens of thousands of miles of cable laid each year in a similar way, consuming over 15,000 tons of copper each year.

Worldwide, some two dozen large ships, of which Tyco Submarine Systems owns eight, are laying undersea cable. To load Simplex' cables, the ships - one or two at a time - tie up at a dock in back of the plant. The finished cable, including repeaters where needed, is unwound from giant storage spools inside the plant, run down a long tramway to the pier and is re-spooled inside the holds of the ships.

Satellites Displaced

In the last five years, under sea cables have displaced communications satellites as the dominant medium for international communications. Today, about 80% of this traffic moves over cables. According to Robert L. Suydam, Simplex' manager of sales and marketing, satellites have become complements to cables. The latter, of course, can't carry wireless communications to cell phones and pagers, and satellites are more cost-effective in reaching the world's many remote, low-population islands.

Why have cables taken over the huge, ever-growing traffic in international voice and data communications? There are two main reasons, says Suydam. First, the success rate in laying cable is 100%, while in con trast, too many communications satellites are destroyed during launch, like the 12 which blew up recently in Russia, or they never achieve the desired orbit or orientation. Second, satellites sometimes fall out of orbit, and it's very difficult, if not impossible, to recover them.

Why have cables taken over the huge, ever-growing traffic in international voice and data communications? There are two main reasons, says Suydam. First, the success rate in laying cable is 100%, while in con trast, too many communications satellites are destroyed during launch, like the 12 which blew up recently in Russia, or they never achieve the desired orbit or orientation. Second, satellites sometimes fall out of orbit, and it's very difficult, if not impossible, to recover them.

Transmissions via cables are also immune to the solar flares and heavy precipitation that can disrupt satellite communica tions. And, unlike satellite traffic, messages carried by cable can't be intercepted. In the rare instance that a cable fails, it can be hauled up, repaired and re-laid. When an early transatlantic cable failed shortly after it was laid in 1865, it was re-laid suc cessfully the following year.

There are still other important advantages to cables. The message-carrying capacity of existing cables has been doubled and even quadrupled with sophisticated new electronics at either end - with even greater increases on tap. The electronics transmit and receive hundreds of thousands of messages simultaneously over a spectrum of frequen cies, not unlike the way a single TV cable delivers a multiplicity of channels. Underwater cables also last for decades. For instance, cables that Simplex made and laid over 40 years ago for SOSUS, the U.S. Navy's offshore network to monitor sub marine and ship activity, are still in operation.

Simplex Technologies: 800/258-7383

Also in this Issue:

- Copper Vital to World Trade

- New "Bronze Age" at Grand Central

- Copper Shines in Radiant Heating

- Copper - Star Energy Saver