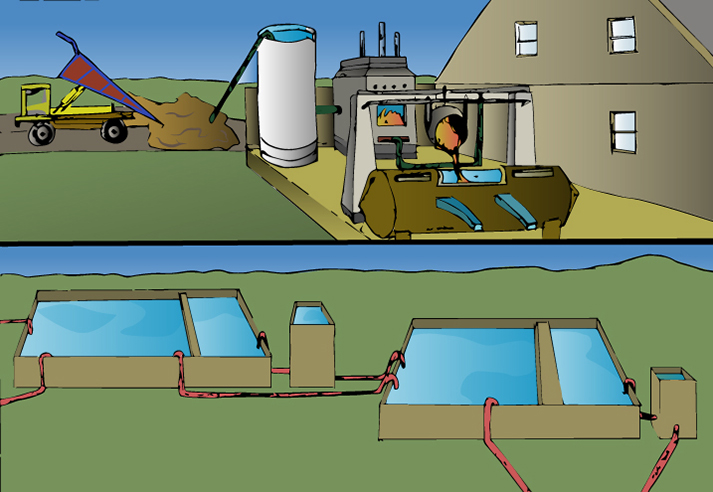

Top: Dried concentrate delivered to smelter. Bottom: Solvent extraction tanks for copper solution leached oxide ore.

Top: Dried concentrate delivered to smelter. Bottom: Solvent extraction tanks for copper solution leached oxide ore.Sulfide Ore: The dried copper concentrates are sent to the smelting operation where it is reduced and melted in several operations. At the end of this melting process the copper is about 99% pure. While this may sound high, it is still not pure enough for electrical applications, so further processing is required.

Oxide Ore: The copper-bearing solution is collected and pumped to the extraction plant where it is purified. It progresses through a number of steps that combine an organic solvent or sulfuric acid to the solution until the copper concentration is high enough for effective electro-plating.