Microbial growth in heating ventilating and air-conditioning (HVAC) systems and their contamination of the indoor air environment is a growing concern. Pathogenic fungi and bacteria that are threats to public health thrive in moist, dark HVAC environments. Researchers have found these conditions to be viable environments for the growth and propagation of harmful microbes. These organisms suspended in indoor air are known to be associated with respiratory infections, chronic lung diseases, airway irritation and sick-building syndrome. The Copper Air Quality Program will design, produce and evaluate copper components for HVAC systems to demonstrate the effectiveness of copper surfaces for reducing the incidence of harmful airborne microbes within these systems and throughout buildings and other indoor civilian and military settings.

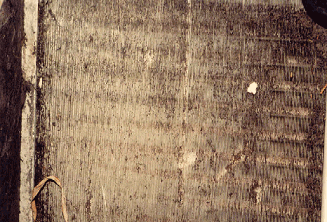

Black mold on air conditioner fins.

Black mold on air conditioner fins.Why Copper? The inherent antimicrobial properties of copper and copper alloys offer an alternative approach to mitigating pathogens and provide the potential for limiting the spread of infectious diseases and allergens through HVAC systems. Research has demonstrated that uncoated copper and copper alloys provide surfaces that have the capability to eliminate many microbial pathogens, viruses and fungi in very short periods of time.

Copper is a naturally antimicrobial engineering material. It is also more thermally conductive, thus more energy efficient, than either stainless steel or aluminum — materials typically used for components in HVAC systems. Studies have shown that surfaces made of copper alloys are effective antimicrobial agents. Copper alloys have been found effective to eliminate pathogenic bacteria within 90 minutes at room temperature and within a few hours at chilled air (indoor air-conditioning) temperatures.

Conversely, microorganisms have been found to survive for up to a month or more on materials such as stainless steel or aluminum.

This study, which is being supported by the U.S. Army Medical Research and Materiel Commnad under Contract No. W81XWH-07-C-0054, is seeking to quantify the potential benefits of copper HVAC heat exchangers, instead of the industry standard aluminum exchanger by monitoring the operational characteristics between HVAC systems that have been retrofitted with copper and aluminum components respectively. The inability of organisms to live and grow on the copper keeps the coils and fins cleaner, resulting in improved thermal transfer to the air flowing across the heat exchangers, leading to improved efficiencies for the entire system.

Jump to: Program Background | Objectives | Hypothesis | Partners | Military Significance | Contacts